Research Overview

Stay hungry, stay foolish.

— The Whole Earth Catalog

Project 1

Manufacturing of novel high temperature aluminum alloys through additive manufacturing cycle.(NSF)

Advancements 1:

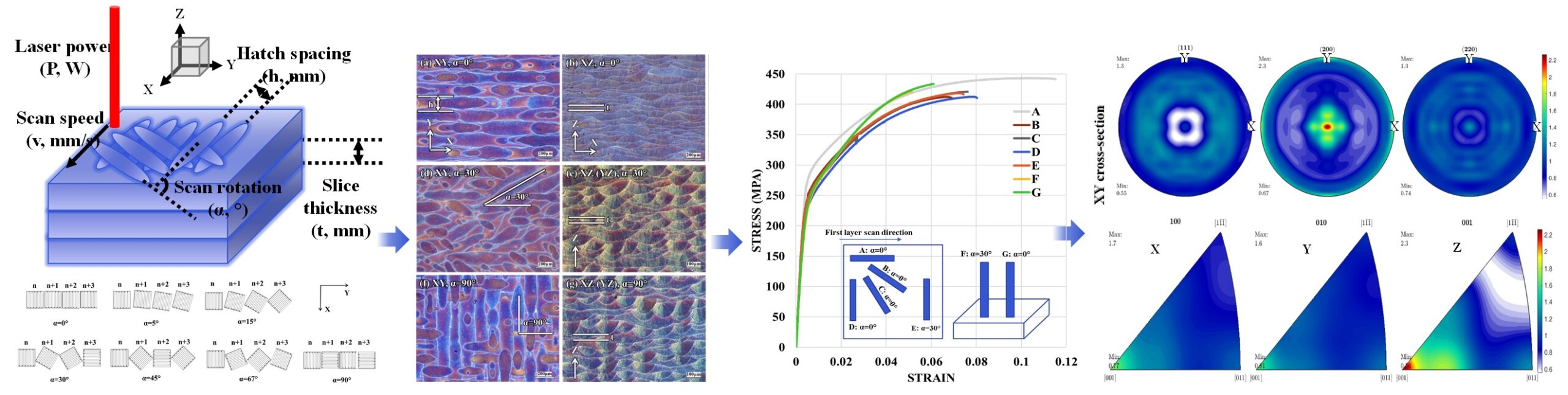

Le Zhou, Haijian Yang, et al. Controlling mechanical properties of laser powder bed fused AlSi10Mg through manipulation of laser scan rotation. Materialia. (2025)

TL;DR: Controlling inter-layer laser scan rotation angles (α) in LPBF-fabricated AlSi10Mg alloy significantly enhances tensile performance, with α = 0° yielding a higher strength and improved ductility due to the alignment of melt pool boundaries with the loading direction.

Advancements 2:

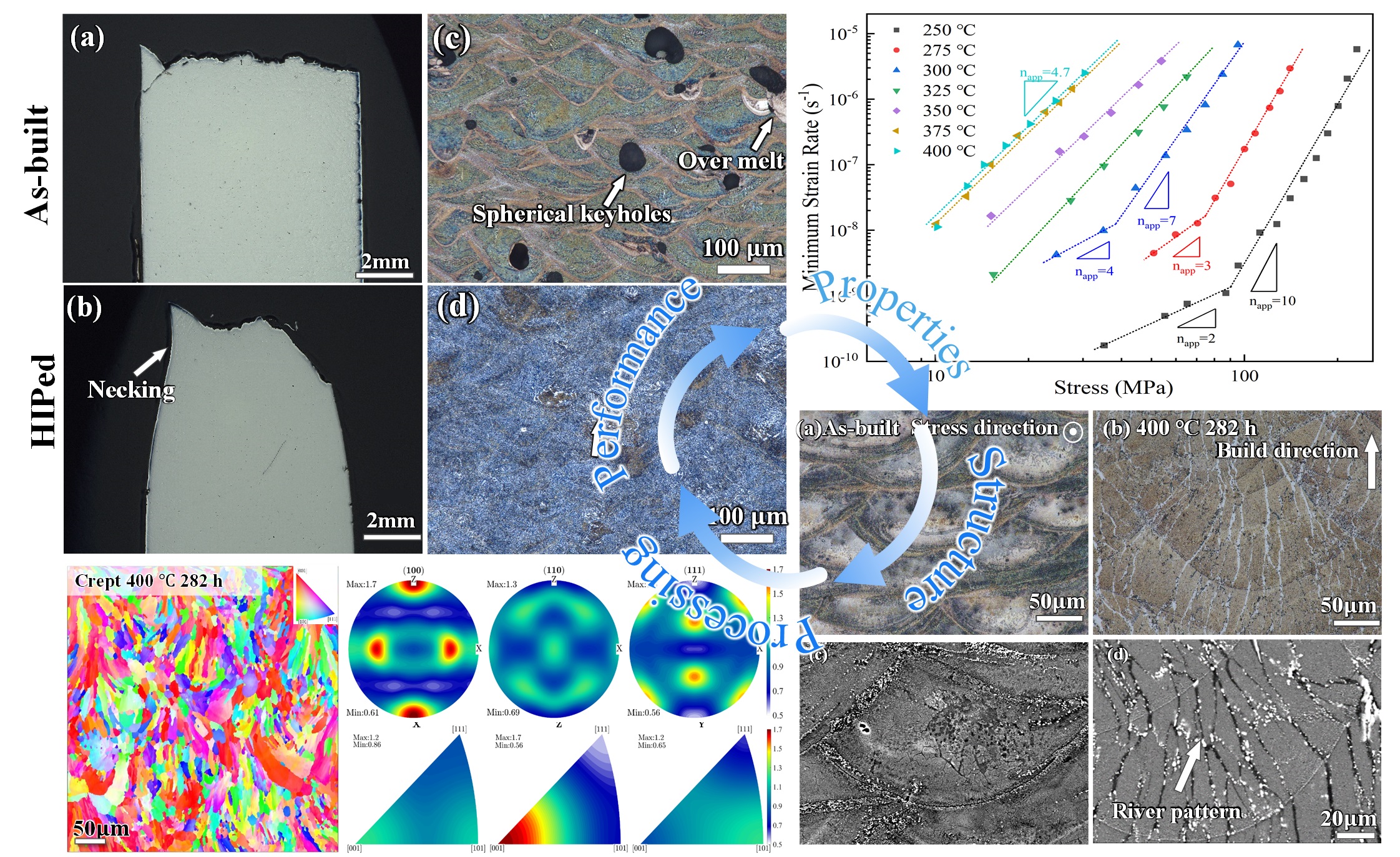

Haijian Yang, Le Zhou, et al. Mechanical Property and Microstructure of Laser Powder Bed Fused Hypereutectic Al16Ce1Mg Alloy. (PDF)

TL;DR: LPBF-processed hypereutectic Al16Ce1Mg alloy demonstrated exceptional printability, tensile strength, and creep resistance enabled by solid solution strengthening, dislocation hardening. Dynamic strain aging-induced PLC effects and Ce-depleted zone evolution governed its strain rate sensitivity and high-temperature deformation.

Advancements 3:

Haijian Yang, Le Zhou, et al. Effect of Zirconium on the Mechanical Properties and Microstructure Evolution of Cast and Laser Powder Bed Fused Eutectic Al-Ce Alloy. (PDF)

TL;DR: L-PBF processed eutectic Al10CeXZr alloys demonstrated excellent printability and enhanced mechanical properties, with Zr-induced grain refinement and precipitation strengthening achieved optimal performance, while statistical analysis identified fabrication method and heat treatment as the key factors governing ductility and strength.

Advancements 4:

Haijian Yang, Le Zhou, et al. Effect of Cerium addition and T6-treatment on the microstructure, tensile, and high-cycle fatigue properties for sand cast A356 aluminum alloy. (PDF)

TL;DR: Modified with Ce and T6 heat treatment synergistically enhance the strength and fatigue resistance of A356 alloy through Al₁₁Ce₃ intermetallic formation and eutectic Si refinement, highlighting a tunable strength-ductility-fatigue balance in Ce-modified Al-Si cast alloys.

Project 2

Printing and Interface Engineering of Colloidal Nanocrystals for Flexible Thermoelectrics and Electronics (NSF)

Advancement:

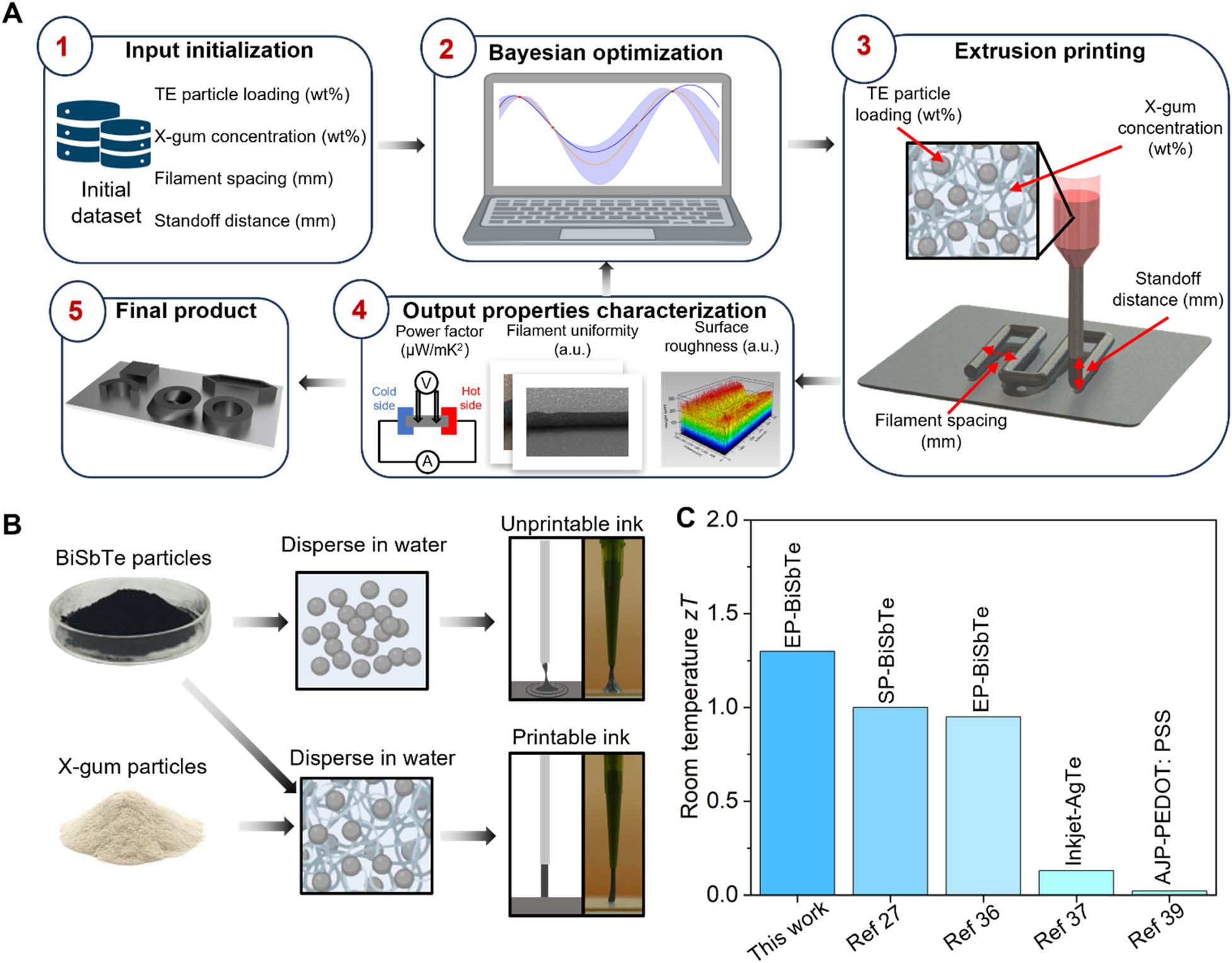

Song K, Haijian Yang, et al. Machine learning-assisted 3D printing of thermoelectric materials of ultrahigh performances at room temperature. Journal of Materials Chemistry A. (2024).

TL;DR: A machine learning-assisted extrusion 3D printing strategy was developed to optimize ink formulations and process parameters, enabling the fabrication of complex-shaped BiSbTe-based thermoelectric materials; thermoelectric performance was further enhanced and electrical conductivity increased through HIP treatment by reducing porosity.

Project 3

Efficient cold-end heat release, cascaded waste heat utilization, and multi-cold source integration in Coal-fired power generation systems. (NKBRDP)

Advancements:

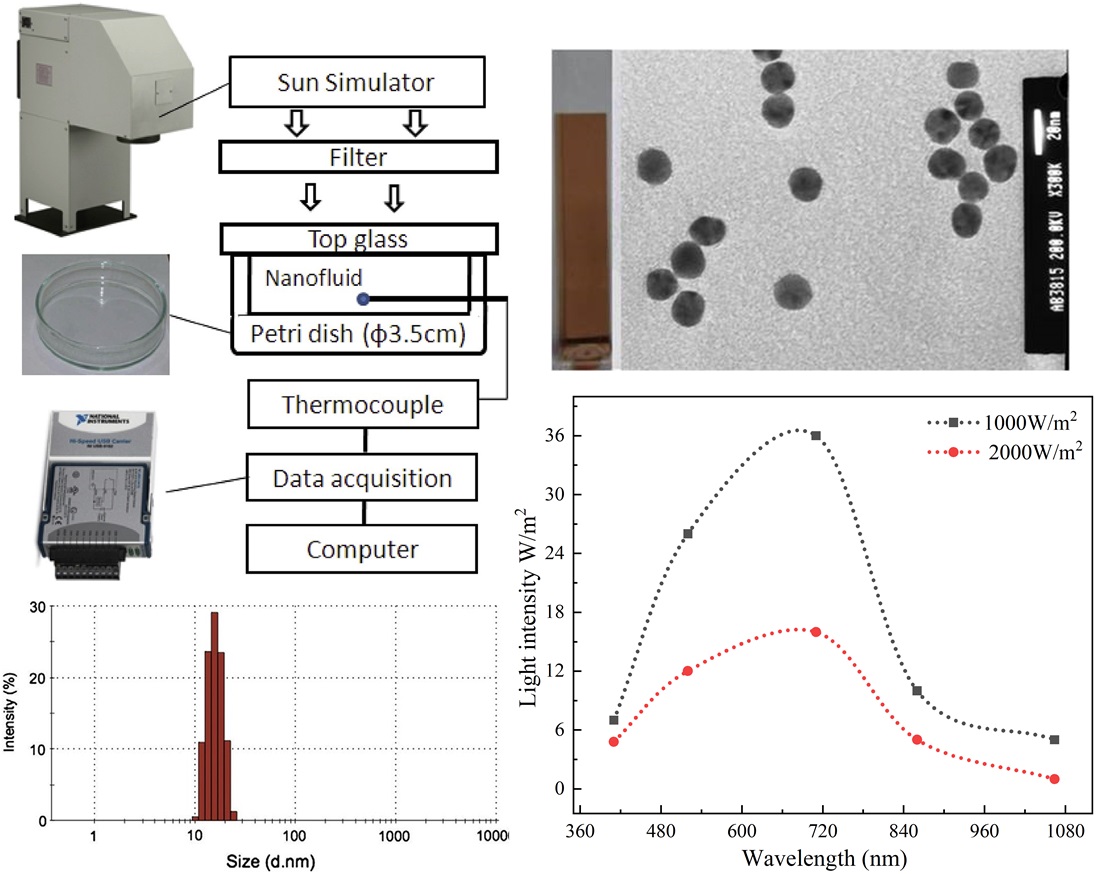

Zhang Hui, Yang Haijian, et al. Photothermal conversion characteristics of gold nanoparticles under different filter conditions. Energy. (2017).

TL;DR: Synthesized gold-nanoparticles exhibited high photothermal conversion efficiency and elevated specific absorption rates (SAR) under VIS-IR illumination, revealing critical property-spectrum relationships for nanoparticle-based thermal management applications.

Independent research initiative:

Advancements 1:

Discrete dislocation dynamics simulation

Haijian Yang. Dislocation-mediated Plasticity and Discrete Dislocation Dynamics.(PDF)

TL;DR: Three-dimensional discrete dislocation dynamics (DDD) simulations using ParaDiS reveal the evolution of dislocation evolution under creep conditions, providing mechanistic insights into steady-state creep behavior and informing lifetime prediction models.

Advancements 2:

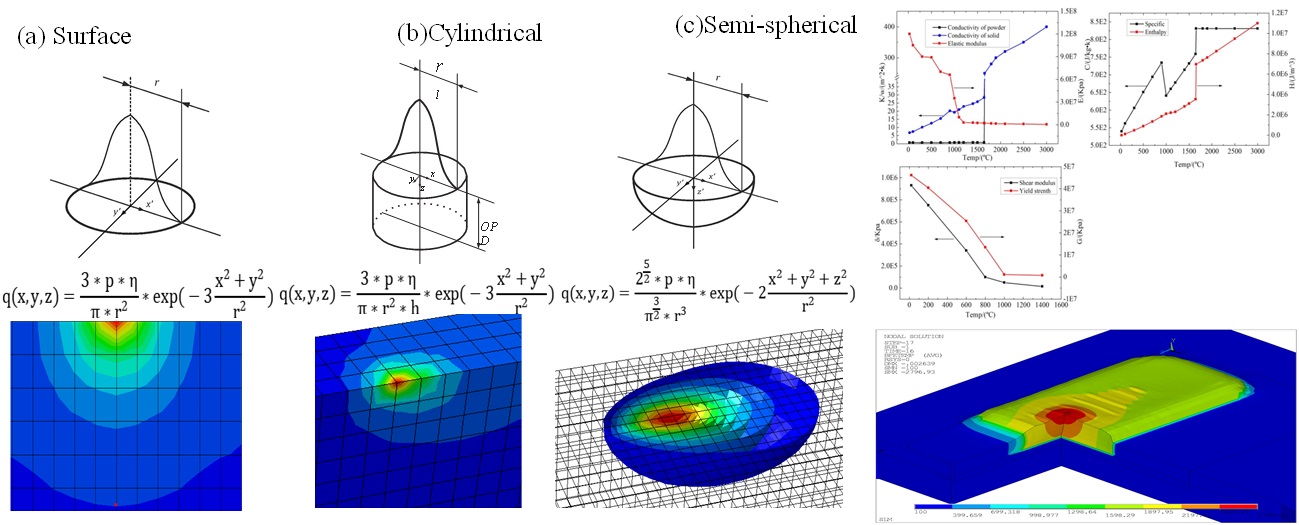

Intelligent Additive Manufacturing System Platform Simulation

Haijian Yang. Macroscopic simulation and experimental measurement of melt pool temperature and stress distribution during selective laser melting of Ti-6Al-4V.(PDF)

TL;DR: Integrating experimentally validated Gaussian heat source modeling with temperature-dependent Ti6Al4V via 3D finite element framework quantitatively revealing the thermal-mechanical coupling behavior in selective laser melting (SLM).